Alexandre Ndayishimiye

While management of plastic waste constitutes a major problem in Burundi, the JENI-ECO COMPANY provides a solution for the population of Gitega (center of the country). It recycles those wastes into paving stones, a solution both for environment and for unemployment.

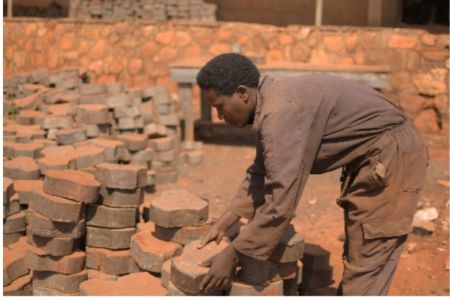

Paving stones recycled

Established in 2020, JENI-ECO COMPANY is a plastic recycling and manufacturing Company based in Gitega city (Political capital), 98 km from the economic capital (Bujumbura).

As indicated by Jean Marie Nizigiyimana, the initiator of JENI-ECO COMPANY, when he established the company, his objective was to protect the environment and offer jobs to young people by recycling plastic waste into paving stones. The first beneficiaries are the inhabitants of his hometown (Gitega), headquarters of the company.

Before the establishment of the company, empty plastic bottles littered the ground

in Gitega city, on every road, avenue, in front of the shops, stores and bistros,

Today, it is no longer the case. The city is clean. All the plastic bottles are collected and transported to JENI-ECO COMPANY and recycled into paving stones. A 50 kg sack of plastic waste collected costs $2.

Recycling process

After collection of plastic waste, it is heated (melting). The liquid obtained is mixed with the sand and the viscous mixture is put in a mold so that the latter gives it a shape desired by the designer.

Recycling process

After this process, they obtain paving stones. Moise Basabose, technical director of JENI-ECO COMPANY explains that they put a lot of efforts in order to have the finished product. “We tried several tests before arriving at an adequate proportion of the mixture to apply for each product,” he explains.

When this company started its activities in Gitega, the paving stones which were made from cement were immediately replaced by those made from plastic waste and sand. Consequently the price of paving stones decreased with added value for buyers who are happy. Paving stones made from plastic waste cost $9 per square meter while those made using cement cost between $10 and $11 per square meter.

Job opportunity

Per day, JENI-ECO COMPANY produces paving stones that cover an area of three to four square meters. Per square meter, that is to say between 22 and 25 paving stones. With 10 sacks of plastic waste and six sacks of sand, they produce 75 paving stones. 20 sacks of plastic waste and 10 sacks of sand produce 100 paving stones.

Apart from full-time employees who supply plastic waste to the company, even the surrounding population benefit from it. They sell plastic waste that they collect in their community. The company employs nearly 20 employees.

Plastic waste collected

Longin Barumbazi, septuagenarian who works in the company participates in the entire paving stone manufacturing process. Before being hired, he was a farmer. Today, with his salary, he has already bought a goat and a pig. The animals give him manure that makes his plants growing well.

Sandrine Kanyange, 20 years old who also works for the company facilitates the heating of plastics and mixing them with sand. “Today, thanks to JENI-ECO COMPANY, I find something to eat. In addition to this primary need, the salary I receive allows me to have my daily needs,” she said.

Dénis ndayiragije, a 25-year-old young man in Karera district (near the headquarters of JENI-ECO COMPANY) appreciates the activities of this company. This agent responsible for collecting plastic waste for the company thanks JENI-ECO COMPANY that he succeeded in getting a job. “I had looked for work everywhere without success. It was when this company opened its doors here that I got my first job,” he said.

Non-recycled plastics, a danger for the population

According to experts, uncollected and non-recycled plastic waste pose a great danger to human health and environment when reused as packaging. It is also dangerous once thrown into lake waters.

For example, traders who use them to package certain products such as palm oil and cottonseed oil.

According to Pierre Ntakiyiruta, professor at the University of Burundi in the Chemistry department, the worst is that when these plastic bottles are exposed to the sun, microplastics are released in large quantities and mix with the oil. When many consumes it, there is a risk of catching serious illnesses such as cancer, etc.

Plastic waste

Claver Sibomana, professor at the same university in the Department of Biology adds that non-recycled plastic waste which is thrown everywhere in gutters and in nature whose final destination is Lake Tanganyika has harmful effects. “A study that was carried out recently shows that they find 10,000 microplastics in that lake,” he stated. What is dangerous, he continues, is that these microplastics subsequently end up in the human body through the aquatic animals that we eat. As an example, he says certain fishes that we eat without emptying their stomach contents worsens cases of cancer.

Both experts conclude that what JENI-ECO COMPANY is doing is commendable. They asked Burundian partners, especially those operate in environment sector, to support this initiative in order to protect both environment and population.